Repairing an ECU/ECM is a highly technical process that requires electronics knowledge, diagnostic equipment, soldering skills, and automotive ECM/ECU repair is a specialized process that requires proper tools, careful diagnostics, and safe electronic handling. This guide explains every step of the ECM/ECU repair procedure so technicians can diagnose, repair, and restore an engine control module correctly.

1. Tools and Materials Needed for ECM/ECU Repair

- Automotive OBD-II diagnostic scanner

- Bench power supply (12–14V)

- ECU pinout diagrams

- Multimeter

- Oscilloscope

- Soldering/rework station

- EEPROM/Flash programmer (KESS3, KTAG, PCMFlash, Autotuner)

- ECU bench harness

- Replacement MOSFETs, voltage regulators, capacitors, drivers

- Contact cleaner

- ESD-safe workstation

2. Safety Precautions for ECM/ECU Repair

- Disconnect the vehicle battery before removing the ECU

- Work on an ESD-safe environment

- Do not touch the PCB with bare hands

- Confirm correct pinout before applying power

3. Removing the ECU for ECM/ECU Repair

- Locate the ECU (engine bay, cowl, under dash)

- Disconnect harnesses carefully

- Remove mounting bolts and extract the ECU

4. Initial Diagnostic Testing Before ECM/ECU Repair

Connect a professional scanner and check for:

- No start

- No communication (U0100)

- Misfires

- Injector/coil driver faults

- Power supply issues

- Immobilizer lock

This narrows down what type of ECM/ECU repair is needed.

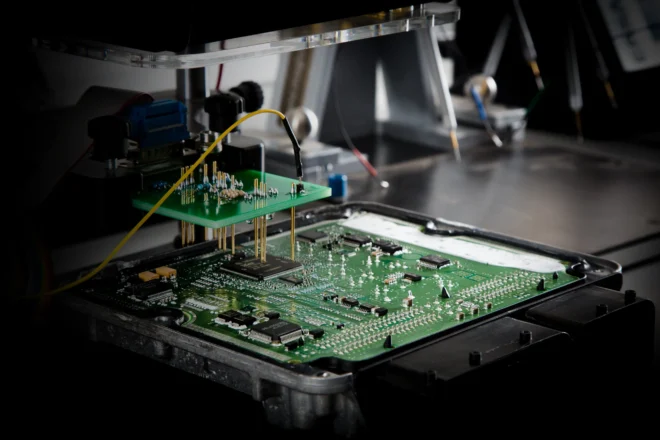

5. Visual Board Inspection During ECM/ECU Repair

Open the ECU and inspect for:

- Burnt or blown components

- Water intrusion or corrosion

- Cold solder joints

- Cracked capacitors

- Damaged MOSFETs

- Rusted connectors

- Broken PCB traces

Clean corrosion carefully with contact cleaner.

6. Power Supply Testing in ECM/ECU Repair

Use a multimeter to confirm:

- 12V main power input

- 5V regulator output

- 3.3V logic supply

- Ground continuity

- Injector/coil driver voltage

Most ECM/ECU repair cases involve power circuit failure.

7. Component-Level ECM/ECU Repair

Replace components such as:

- Power drivers

- MOSFETs

- Voltage regulators

- Diodes

- Capacitors

- Micro relays

- Transistors

Use quality parts and add thermal paste where required.

8. EEPROM & Flash Memory Repair in ECM/ECU Repair

If firmware is corrupted:

- Use KTAG, KESS3, PCMFlash, Autotuner

- Read EEPROM + Flash

- Fix checksums

- Restore IMMO, VIN, ISN

- Rewrite firmware

- Replace memory chips if physically damaged

This is a common step in advanced ECM/ECU repair.

9. Bench Testing After ECM/ECU Repair

Use a correct bench pinout to test:

- 12V power input

- CAN communication

- Sensor reference outputs

- Injector/coil driver signals

- IMMO communication

An ECU must behave like it does in the vehicle.

10. Reinstallation After ECM/ECU Repair

- Reinstall ECU

- Reconnect harness

- Reconnect the battery

11. Final Vehicle Testing After ECM/ECU Repair

Verify:

- Engine starts immediately

- No fault lights

- Stable idle

- Proper injector firing

- Normal throttle response

- Correct sensor readings

- Boost operation (turbo vehicles)

Important Notice About ECM/ECU Repair

ECM/ECU repair should only be performed by trained electronics technicians. Incorrect procedures can damage coils, injectors, power circuits, or the entire electrical system. If you are not comfortable with micro-soldering or ECU flashing, professional repair services like FixECM are recommended.

Additional Resources

Contact FixECM

📞 647-247-8555

📞 1-800-915-5566 (Toll-Free)

📧 info@fixecm.com

🌐 https://www.fixecm.com